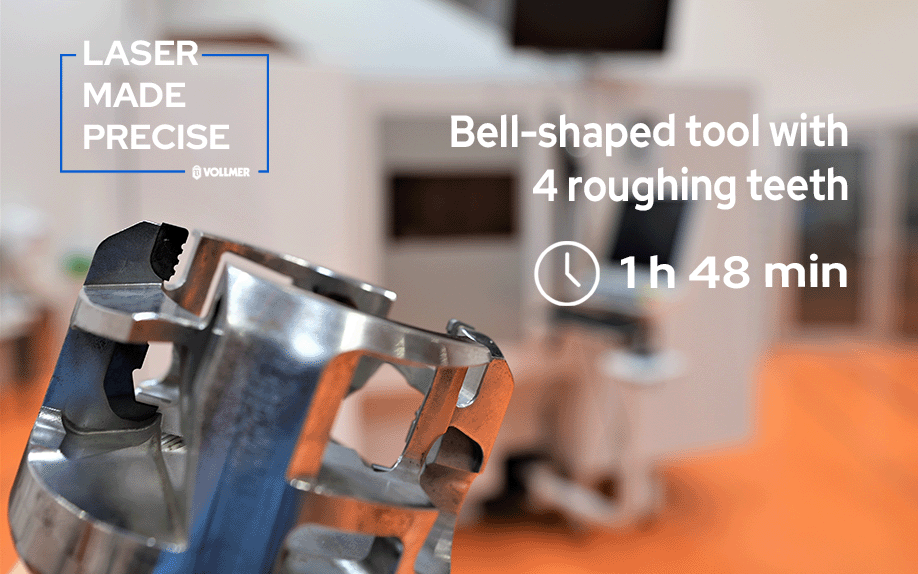

Close-up

At VOLLMER, we take on even the most complex challenges in tool machining. A current example: a closed bell-shaped tool with roughing teeth, manufactured on our latest VLaser 370.

The tool is used in particular in automotive engineering and aerospace technology for machining aluminium and die-cast parts.

THE CHALLENGE

Tools of this type place the highest demands on:

- Initial situation – Four teeth without profile with a PKD plate thickness of 2 mm / diameter 52.176 mm / length 99.852 mm

- Closed geometry – difficult to access for processes such as wire EDM and impossible for disc EDM

- Roughing gear cutting – requires many compensating movements during machining

- Clamping – very short tool length and clamping depth

our solution: the VLaser 370

Thanks to our unique machine concept with machining directly at the pivot point, wear-free linear drives and direct clamping, the VLaser 370 masters these challenges with maximum precision and efficiency.

the result

- Processing time including measurement: only 1 hour and 48 minutes

- Outstanding surface quality

- Minimal tool wear

Maximum cost-effectiveness -

even with complex high-precision tools

The VLaser 370 sets new standards in the machining of PCD tools – for the most demanding requirements in all industries.