The VLaser 370 - Precision meets innovation // Part 1 2020-03-09

to overviewWhy a laser? Why from VOLLMER? Because in addition to eroding and grinding, this laser process completes our range for machining rotary tools. Because we want to offer you more than just one very specific process. We want to provide you with exactly the process you need. We have developed the VLaser 370 precisely for ultra-hard materials such as PCD, CVD-D and MCD – for high machining flexibility and the best quality and surface finish. With tensioning options of 150 mm in diameter and up to 250 mm in length, it is highly versatile.

Our solution with high-precision kinematics

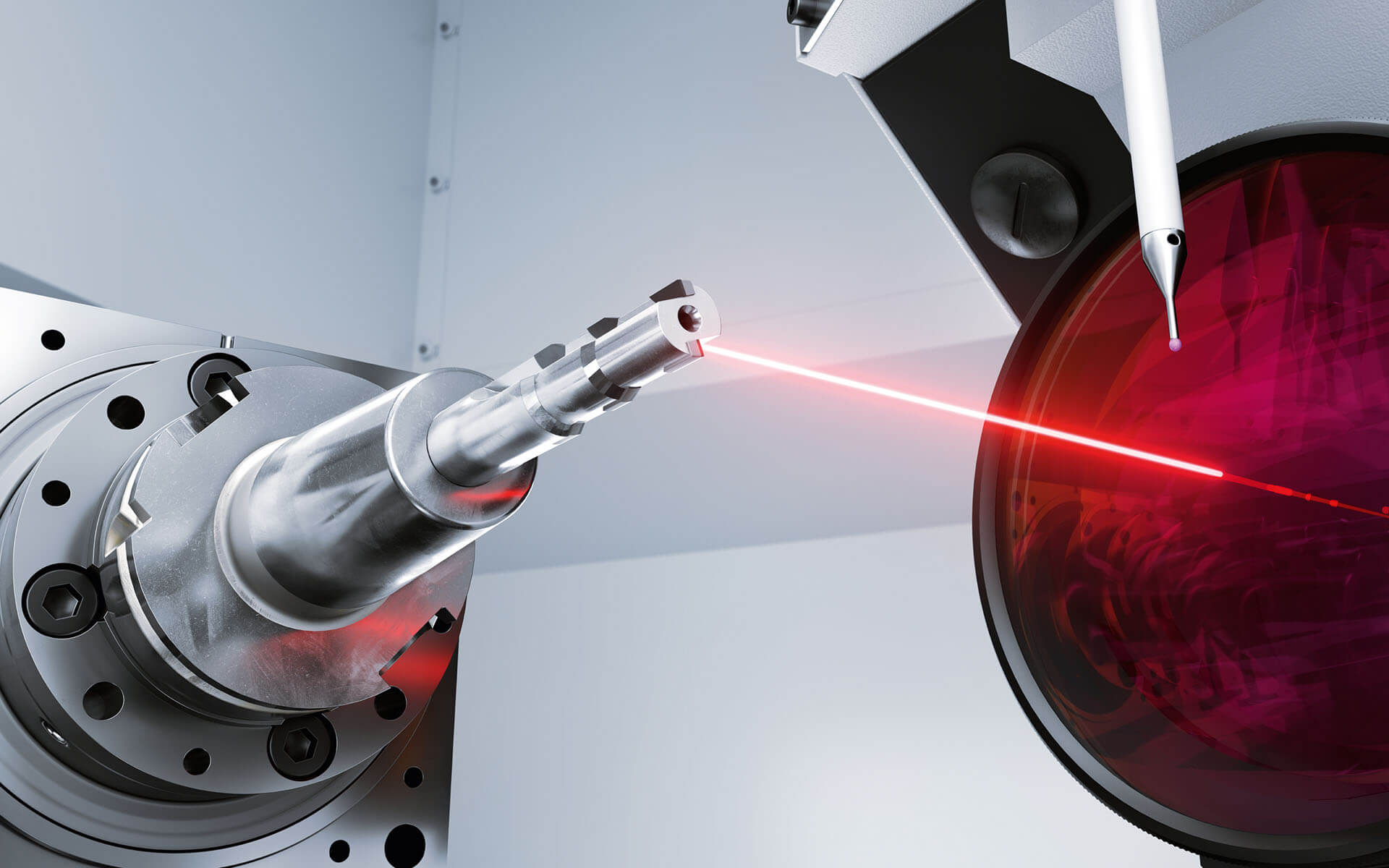

At the core of the VLaser 370 is its fixed laser beam guidance with innovative machine kinematics. The way in which the five axes are arranged on top of each other means that the tool is always machined at the pivot point of the C-axis. This makes it possible to machine tools with minimal axis movement and to ensure stable process control. At the same time, the kinematic chain enables high path accuracy, which has a positive impact on the machining accuracy and quality of the tools.

Unique on the market – optional counter point

The VLaser 370 can optionally be equipped with a counter point to achieve even higher concentricity. This makes the VLaser 370 the first laser machine on the market to have such a counter point.

Horizontal beam guide – no misting, no soiling

The laser in the VLaser 370 is positioned such that the beam guide is horizontal. Thanks to the horizontal arrangement, rising vapours do not cause misting or soiling of the optics.

You can find further highlights of the VLaser 370 in part 2.