„As a full-line supplier, we can advise independently of a particular technology“ 2020-10-26

to overviewGenerating enthusiasm for the machines through customer-oriented product development: Jürgen Hauger, Director Sales at VOLLMER, and his team are in direct contact with customers and know their concerns. His unfiltered experience gained from numerous discussions with customers and interested parties provides valuable knowledge for the development of machines such as the VLaser 370. Where does he see the strengths of the new technology in the VOLLMER portfolio?

Editorial team: Mr. Hauger, from your perspective, what are the advantages of the new laser machine VLaser 370 from Vollmer?

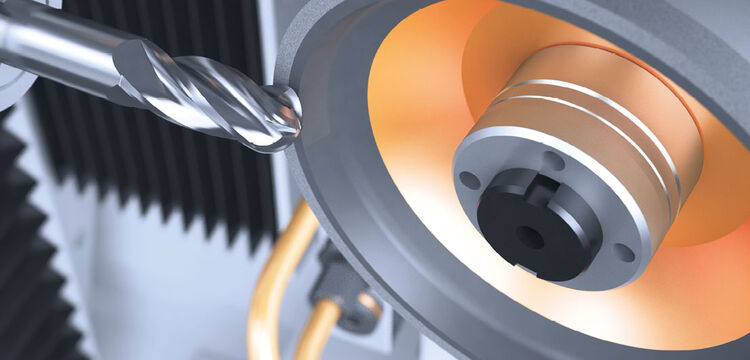

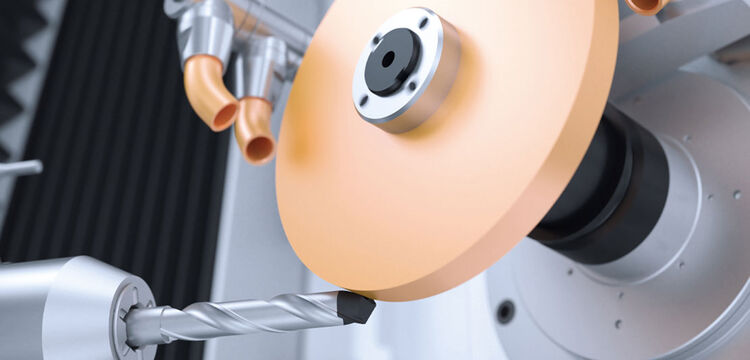

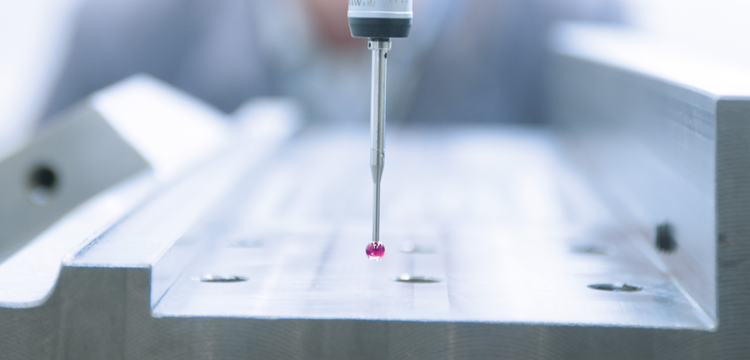

Jürgen Hauger: Compared to laser machines from our competitors, we want to score points not only with high productivity and a good price/performance ratio, but also with our holistic approach as a full-line supplier. The laser is a useful addition to our grinding and eroding machines. We have applied all our experience from precision engineering to the VLaser 370. As with the VGrind family, the VLaser 370 is characterised by innovative kinematics which, based on the C-axis arrangement, always keeps the tool in focus in order to machine a cutting edge with high precision and stability with as little movement as possible. The VLaser 370 is also the first laser machine on the market with an optional counter-point.

Editorial team: What was the biggest challenge you or your department faced in this project?

Jürgen Hauger: Laser processing is a new processing technology for VOLLMER and the sales team. We have been the technology leader in the fields of grinding and eroding for decades and are continuously improving these machines, but we were still missing the laser. The laser enables us to provide our customers with the best possible advice, regardless of the technology involved, in order to offer them individual solutions. Does this make us a generalist? Yes and no. Because we actually see ourselves as specialists - in every field. This is our claim and at the same time the challenge for the entire VOLLMER team to build up comprehensive know-how in all areas. But this is exactly what VOLLMER's strength has been for 111 years.

Editorial team: Which companies do you see as the primary customer group for the VLaser 370?

Jürgen Hauger: All companies worldwide that machine cutting rotary tools in the field of ultra-hard materials such as PCD, CVD-D or MKD. The laser machine is specifically designed for sharpening tools with an outer diameter of up to 150 millimetres. The VLaser 370 can be used both for production and for resharpening ultra-hard cutting materials.

Editorial team: What is currently moving you most with regard to the VLaser 370?

Jürgen Hauger: With the VLaser 370 we have succeeded in creating a convincing machine and our customers should finally experience this live. The corona pandemic has thwarted our plan to present the machine in the usual manner early this year at our world's leading trade fair, the GrindTec. We in the sales department are in the starting blocks, are highly motivated and cannot wait to present the machine to all interested parties and to receive feedback. But surely another time will come. Despite Corona - we are still there for interested parties. We will be happy to provide advice on site in Biberach in the usual quality, taking the usual precautions into account. Or customers can visit us digitally: We prepare a virtual live demonstration individually for their requirements. We look forward to hearing from you.