The linear motor in use 2020-05-11

to overviewThe direct drive technology of motors is perfect when it comes to increasing productivity, accuracy and dynamic performance. In the VLaser 370, in addition to the rotary axes, the linear axes are also designed as direct drives (linear motors). The advantage: In comparison to ball screw drives, linear motors do not require mechanical transmissions such as racks with pinion, drive belts or gears. They therefore operate without contact and are not subject to wear. Together with glass scales as a high-quality displacement measuring system, this results in an unbeatable combination.

Operating principle direct drive

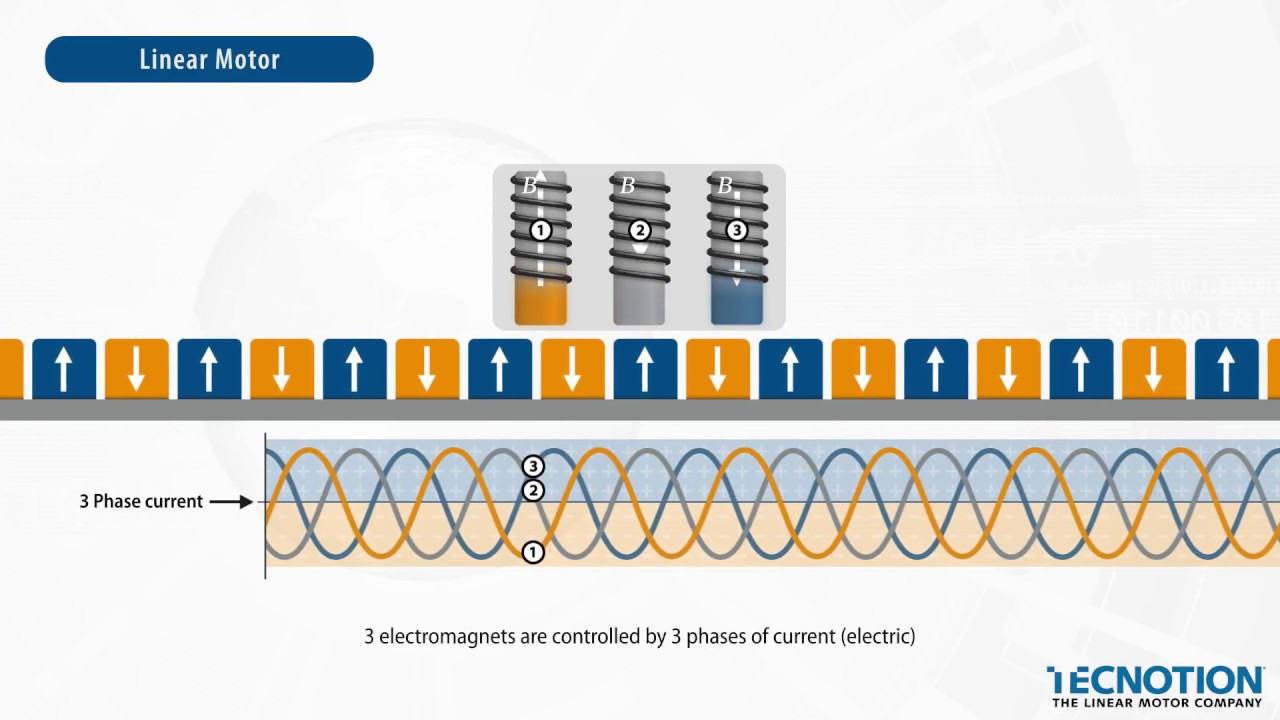

With direct drives such as torque and linear motors, the force of the drive element is transmitted directly to the load to be moved without mechanical transmission components but with electromagnetic forces. Both types of drive basically work according to the same operating principles. In contrast to the torque motor, however, the electromagnets in the linear drive are not arranged in a circle around a rotor, but - as the name suggests - linear. So just imagine the linear motor as a torque motor that has been cut open and unrolled producing a torque along a straight plane.

A direct drive always consists of two parts: A moving stator with copper wire windings (coils) and a carrier of permanent magnets, which is the stationary part of the linear motor. When a current flow is generated in the coil unit of the stator, a magnetic field is formed there. When the current phases in the coils change, the polarity of the individual coils changes and an electromagnet is created. The attraction and repulsion forces between the coils and the magnets of the magnetic plate create a linear force and move the coil unit forward. When the direction is changed, the polarity is simply reversed, acceleration and speed can be controlled via the frequency of the AC voltage. This is comparable to the drive technology of a magnetic levitation train.

Advantages of the linear drive?

Due to this mode of operation, the linear motor can completely do without force-transmitting components. By eliminating such components, the linear motor impresses with high acceleration, precision, dynamics and repeatability (in the measuring system and in the linear unit). These characteristics are essential for the VLaser 270 as a modern machine solution. At the same time, the non-contact method reduces the number of wearing parts, since only the linear guides are stressed.

"In addition to the VLaser 370, we already use linear drives in our tool grinding machine VGrind 340S. And we will continue to equip further machine models with this technology in the future", says Manfred Sägmüller, Head of the R&D department at VOLLMER: "We are convinced that this drive, due to its complete contact-free operation, provides features not only for the VLaser 370 that offer added value to our customers".

Video source: Tecnotion GmbH, Munich - www.tecnotion.com (https://www.tecnotion.com/video.html)